Do you usually design things?

‘We are normally the executing party. Snijlab is a webshop: we use a laser to cut out designs that customers deliver to us digitally. We make anything on a flat plane for individuals and companies; from birth announcements cut in wood to huge plastic plates for the creative sector. We design a lot internally and once made a well-known design: a wooden folder for a notepad. But this is the first time that we are producing a design of our own on such a large scale.’

Why face shields?

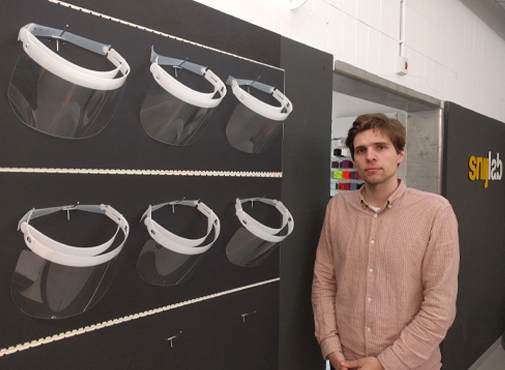

‘Due to Corona, there is a great demand in the healthcare sector for face masks, glasses and splash shields. These are – always – necessary to protect healthcare personnel from coughing and sneezing patients. The National Resources Consortium of the Ministry of Health, Welfare and Sport appealed to the market to rapidly develop non-profit medical devices for which a shortage is imminent. Our face shield is a combination of glasses, face mask and splash shield in one.’

How did you come into contact with Erasmus MC?

‘A colleague of ours knew someone there and showed them our prototype. He was immediately enthusiastic. In consultation, we made the screen a bit smaller and chose other material that can be properly disinfected. Erasmus MC immediately ordered 10,000 of the final model. We are now busy with production. The screen consists of four flat parts that we cut ourselves. Then those parts have to be assembled.’