First circular built biolab in the world opens in former tropical swimming pool

Showcase

BlueCity opens a breeding ground where making an impact through biocircular design and biobased technology is central. BlueCity Lab opens its doors to biotechnologists, designers and innovative companies. The place is ready for experimenting with materials and products of the future. Think of leather made from plants, self-healing concrete from bacteria or an urn made from fungi. The Rotterdam Alderman for Sustainability, Arno Bonte, opens this place during a festive online moment.

Although the innovations are still experimental, the reason to start is dead serious. “The market urgently needs alternatives. Products that have been designed in a sustainable and smart way, with future-proof materials, so that we will soon have no waste at all, ”says Nienke Binnendijk, director of BlueCity Lab. “Accessible places with our facilities, for experiments and knowledge sharing, are crucial to make this waste-free economy become reality within ten years.”

Essential combination of labs

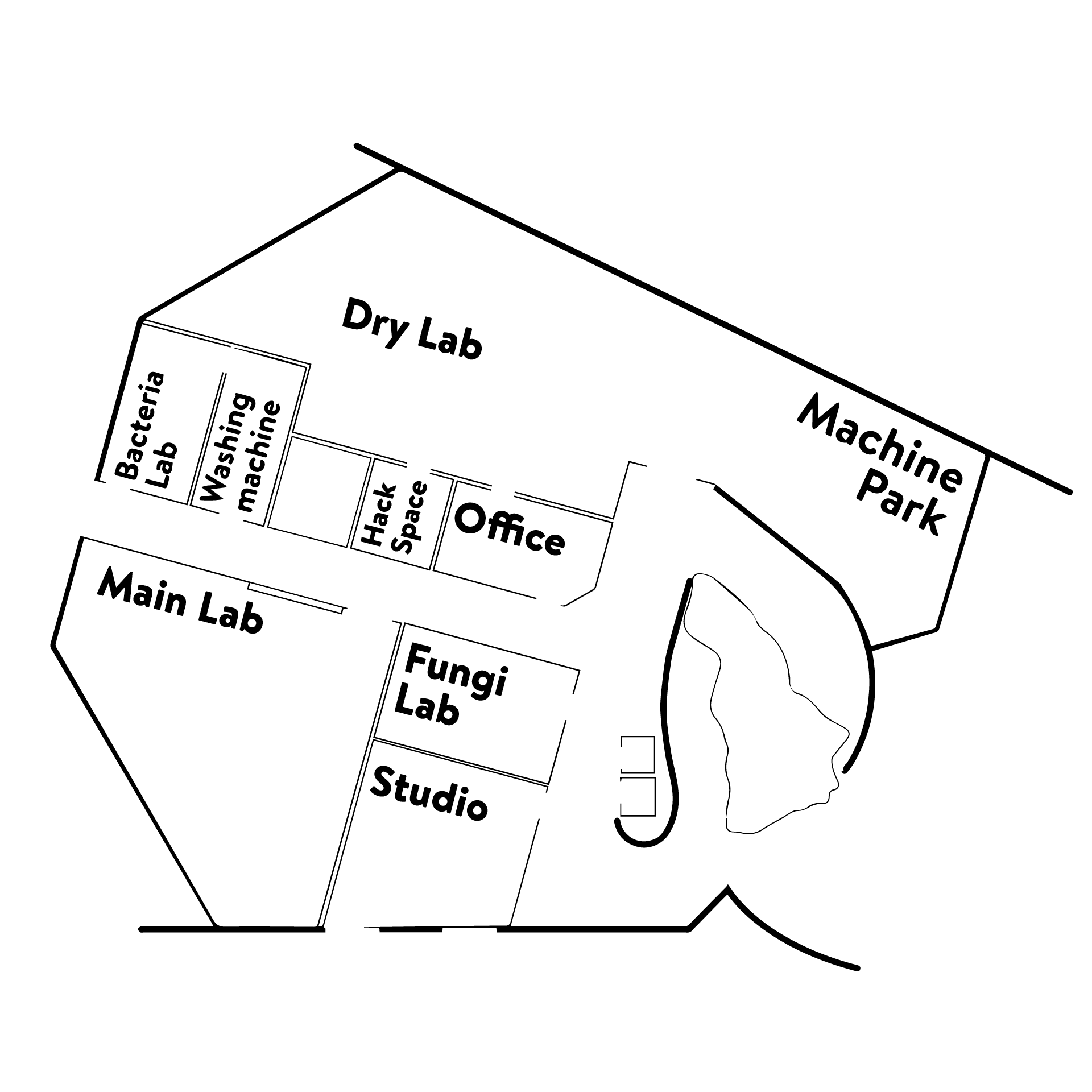

With the support of partners like DOEN Foundation, Rabobank Rotterdam and the Municipality of Rotterdam, Binnendijk and her team realized a space of more than 2,000 m², consisting of a lab to experiment with fungi, a bacterial lab and a general lab for light biochemical work, supplemented with a workshop with 3D printers, a CNC mill and woodworking machines. “This combination of spaces is unique and vital,” says Binnendijk: “In the labs you grow material, in the workshop you convert it into a product. This way you can develop and test your prototype.” In collaboration with Rotterdam University of Applied Sciences, the BlueCity Lab also prepares students from a circular practical situation for the labor market of the future.

New bio solutions thanks to extra space

The BlueCity Lab provides space for pioneers such as Lori Goff, who develops UnPlastic, a compostable packaging material from beer brewing waste. Marjanne Cuypers-Hendrikson develops SeaWood, an environmentally friendly alternative to chipboard, Willem Flinterman tests the breakdown of polystyrene foam and polyethylene by mealworms and fungi, which saves a lot of emissions and Emma van der Leest, founder of the BlueCity Lab, is working on her cultivated materials. Binnendijk opens the Lab dressed in a top of biodesigner Ilse Kremer, colored with pigment from fungi. This innovation has the potential to drastically cut the negative impact of coloring in the fashion industry.

Circular renovated laboratory

By realising BlueCity Lab and the FoodHub, a little further down the hall, with recycled materials – by many seen as an impossible task, given the demands placed on these types of spaces – a total of 112.000 kg CO2-equivalent was saved; enough to drive a car 643 times from BlueCity to Paris and back, or one and a half times to the moon. The Lab also runs on solar panels.

BlueCity